Raw Materials

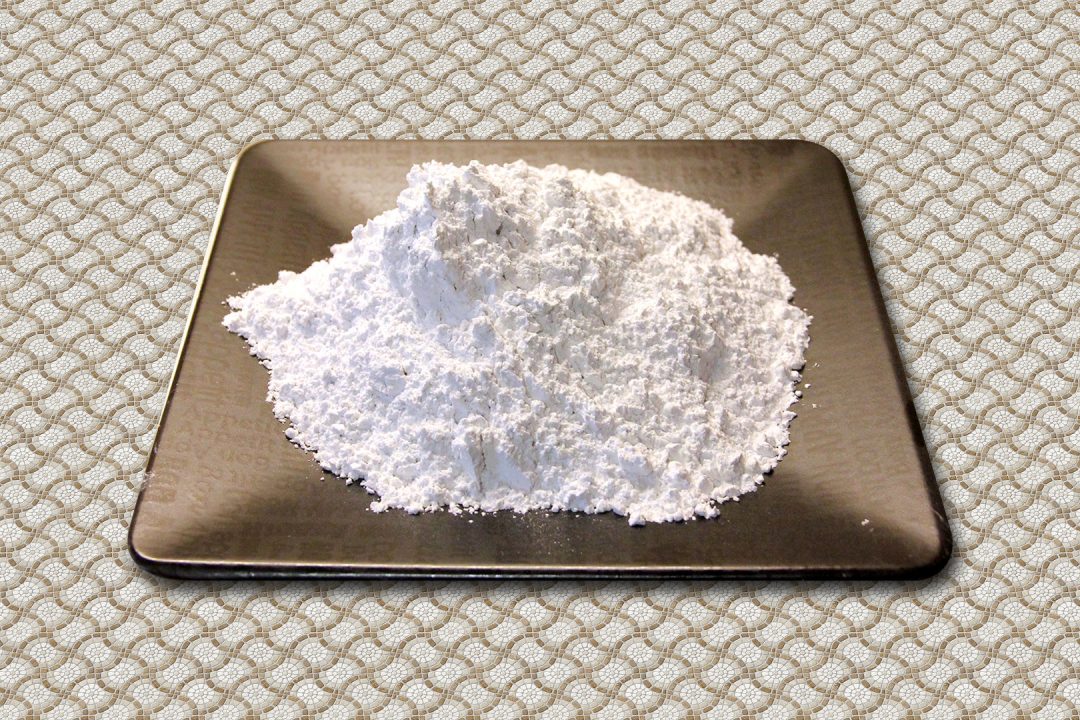

Zirconium Silicate

Zirconium silicate obtained by grinding zircon sand is a raw material that is used in high amounts in the ceramic, porcelain and vitreous ware industry with its opacifying & whitening effect.

Zirconium Silicate is also used in the refractory industry because it increases thermal shock resistance.

It is also used in the casting industry due to its high thermal conductivity.

There are Zirconium silicate materials with different grain sizes in our company.

Aluminum Oxide (Al 2 O 3 )

Aluminum oxide is formed by the easy reaction of aluminum with oxygen and is generally used as an abrasive.

Aluminum oxide is one of the most used raw materials in the world. It can be supplied in different grain sizes and purity. Main areas of use:

– Abrasive industry

– Glass industry,

– Ceramic industry,

– Refractory insulation materials

Where Aluminum Oxide is used, it increases chemical stability, refractoriness, thermal shock resistance and abrasion resistance. Its melting point is around 2050°C and it significantly increases the melting point of ceramic glazes. The row also gives a wide melting interval. Al 2 O 3 It increases the viscosity of glazes and also provides the glaze to gain chemical resistance.

wollastonite

It is used as a source of calcium oxide in ceramic glazes and muds and is preferred because it does not cause outgassing compared to other carbonate-containing calcium oxide sources (calcite). Wollastonite, which can be used in ceramic mud and glazes, reduces the firing temperature by showing a melting feature in the mud. Wollastonite muds are resistant to temperature changes.

Barium Carbonate (BaCO 3 )

Barium carbonate is a white, powder or granular chemical raw material. Barium carbonate is generally used as a source of BaO (Barium oxide) in ceramic frit production. Brightness and opacity levels can be adjusted according to the amount of use.

Zinc Oxide

Zinc Oxide (ZnO) plays a role in preventing cracking in glazes with its low expansion coefficient. It is available in various qualities. (Golden Seal, 99.7 percent etc.)

Titanium Dioxide (Rutile, Anatase)

Improves chemical resistance and stabilizes cracking. Rutile is the most common form of TiO 2 in nature. It mostly contains significant amounts of Fe, Nb and Ta. It is generally used in the paint industry. Anatase is used in the food and cosmetics industry.

Calcined Aluminum Oxide

It is used in refractory, brick, glass, ceramic, frit and enamel, construction chemicals, industrial paints and abrasive industries. It has fine grain size and homogeneous grain distribution. The calcination process was carried out at high temperatures. It has more than 99 percent purity. It provides high gloss, covering and whiteness. Thanks to the high whiteness it provides, it reduces the use of zircon.

TALC

The use of Talc in ceramic bodies provides control of thermal expansion. It is characterized by its high coefficient of expansion, which helps glaze-body harmony at low temperatures. It has an adverse effect at high temperatures and is used to increase the thermal shock resistance of ceramic products sintered at this temperature.

Drained Kaolin

Kaolin is the name given to a group of clay minerals within the clay minerals classification. The most important

mineral of the group is Kaolinite (Al2Si2O5(OH)4) and other minerals of the group are stalagmite, nacrite and halloiside.

Kaolinite is a clay mineral with aluminum hydro silicate composition.

Kaolin in Ceramic Industry: Generally, kaolins containing 75-80% kaolinite mineral are preferred. Firing color, viscosity, resistance to friction, very low Fe 2 O 3 and TiO 2 ratios and 83-91% gloss are required.

.jpg)

English

English